Machine Tool

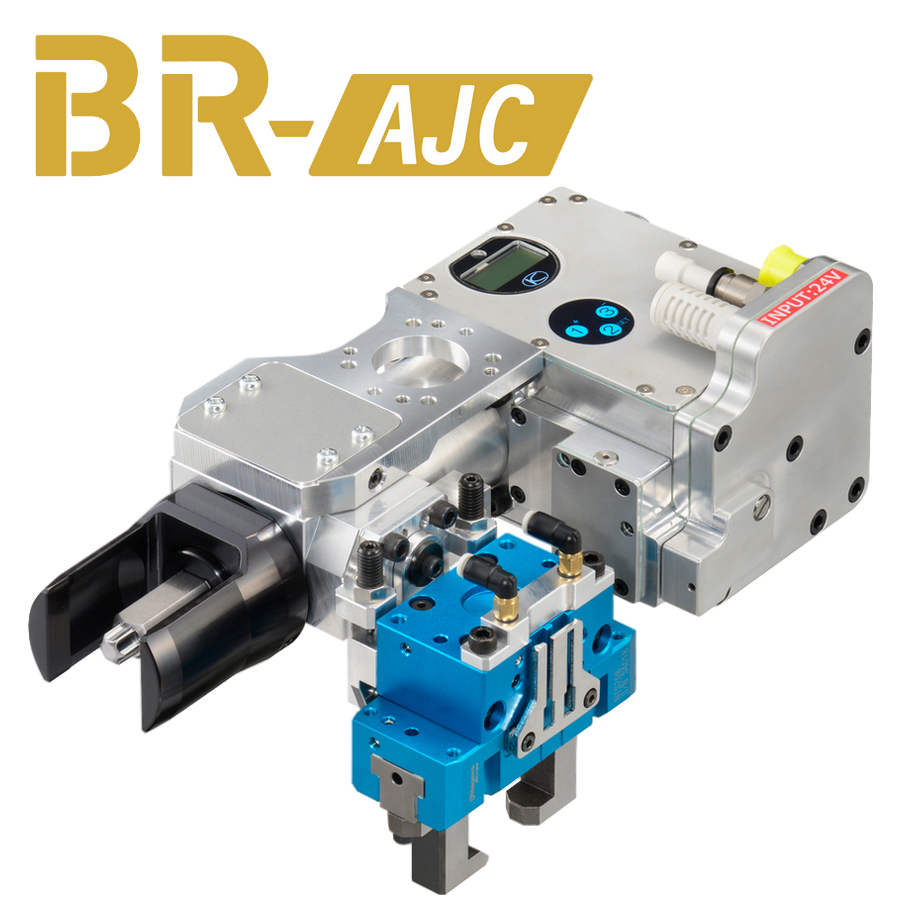

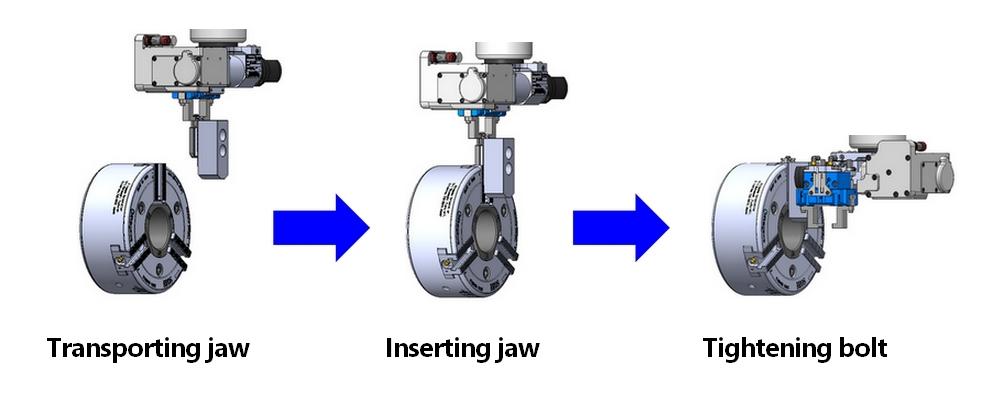

This video introduces the features of BR-AJC_E.

| Model | BR-AJC06E | BR-AJC08E | BR-AJC10E | |

|---|---|---|---|---|

| Dimensions | Length (mm) | 265 | ||

| Height (mm) | 140 | |||

| Width (mm) | 139 | |||

| Mass (kg) | 5.5 | |||

| Tightening torque (Nm) | 47 | 80 | 107 | |

| Applicable chuck | BR06 / BRT06 | BR08 / BRT08 | BR10 / BRT10 | |

| Applicable soft jaws ※Allowable jaw height: 56 mm |

SJ06B1 |

SJ08B1 SJ08S1 SJ08A1 SJ08A1-056 SJ08A1T056 |

SJ10B1 SJ10S1 SJ10A1 SJ10A1-056 |

|

※Please machine the jaw so that the maximum jaw height is 56mm or less.

| START | Air supply | OFF= Stop、ON= Rotation | |

|---|---|---|---|

| Load | Solenoid valve (DC24V/50mA or more) | ||

| DIR | Rotating direction | OFF= Right rotation (tightening)、ON= Left rotation (Loosening) | |

| Load | Solenoid valve (DC24V/50mA or more) | ||

| LOW | OFF= Tightening・Loosening、ON= Slow reverse rotation | ||

| Load | Photocoupler (DC24V/20mA or more) | ||

| Control signal input | STOP | Stop | ON= Set torque reached or error detected |

| Output | Open collector (DC24V/30mA or less) | ||

| ERR | Error | ON= Error detected Condition for turning ON ・Insufficient torque during tightening : Timeout of tightening timer (10 sec) ・Limit torque reached during loosening : Reach 160Nm ・Overtorque : More than 20Nm above the set torque |

|

| Output | Open collector (DC24V/30mA or less) | ||

| Power source | DC24V/10W or more | ||

| Adjustable torque range | Tightening : 20~150Nm Loosening : 160Nm |

||

| Indicator lamp | Green: Synchronize with START signal and turn on | ||

| Red : Synchronize with ERR signal and turn on | |||

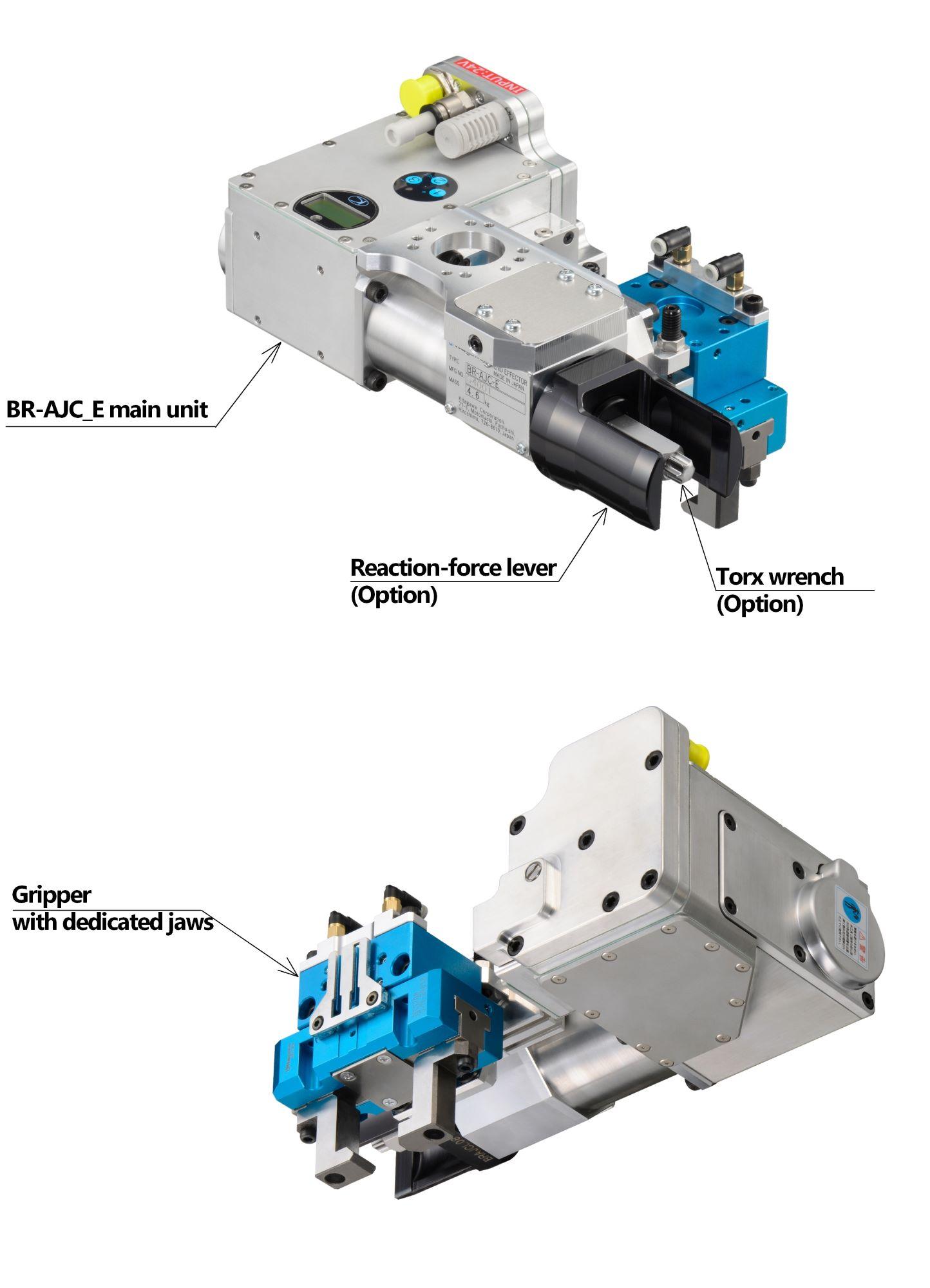

| Main unit | Reactoion |

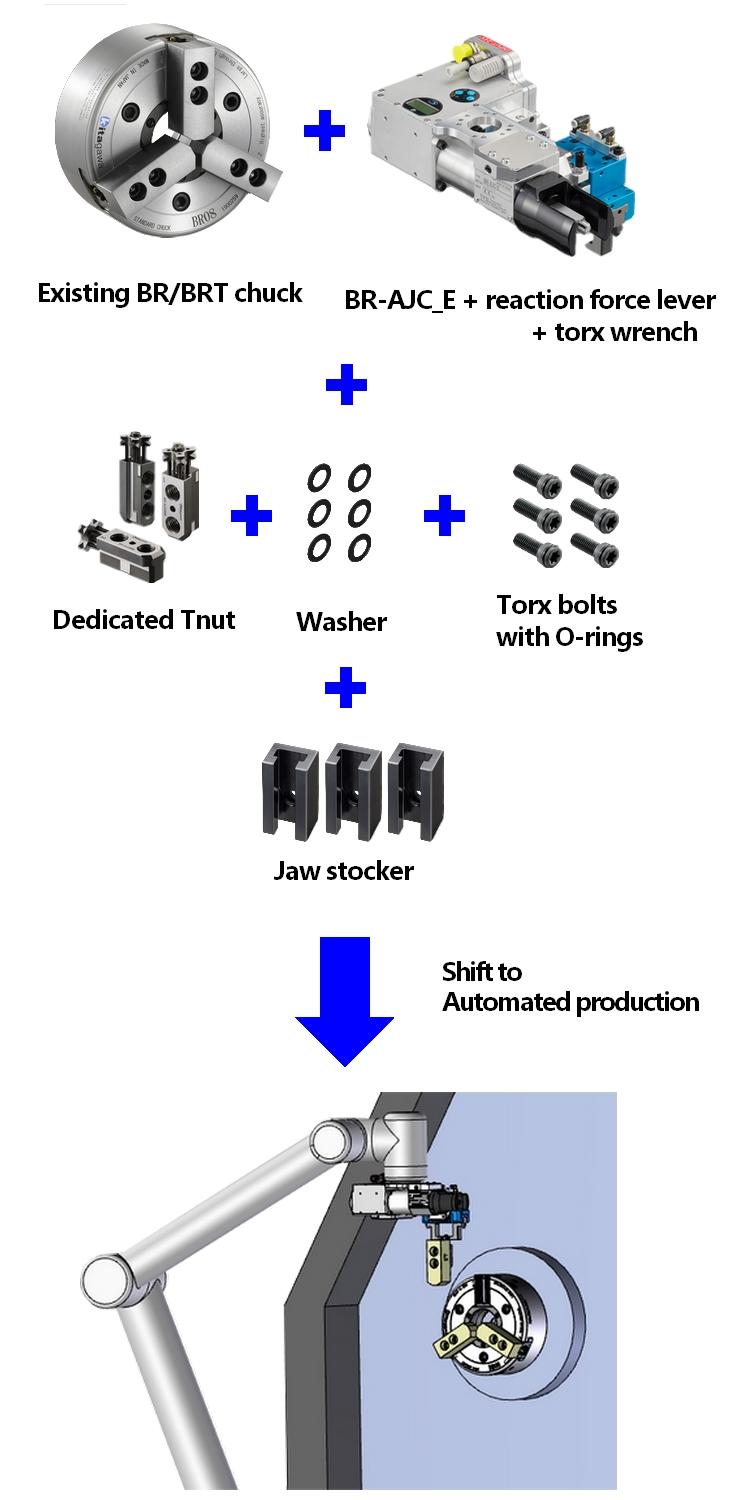

Washer | Jaw stocker |

||||

|---|---|---|---|---|---|---|---|

|

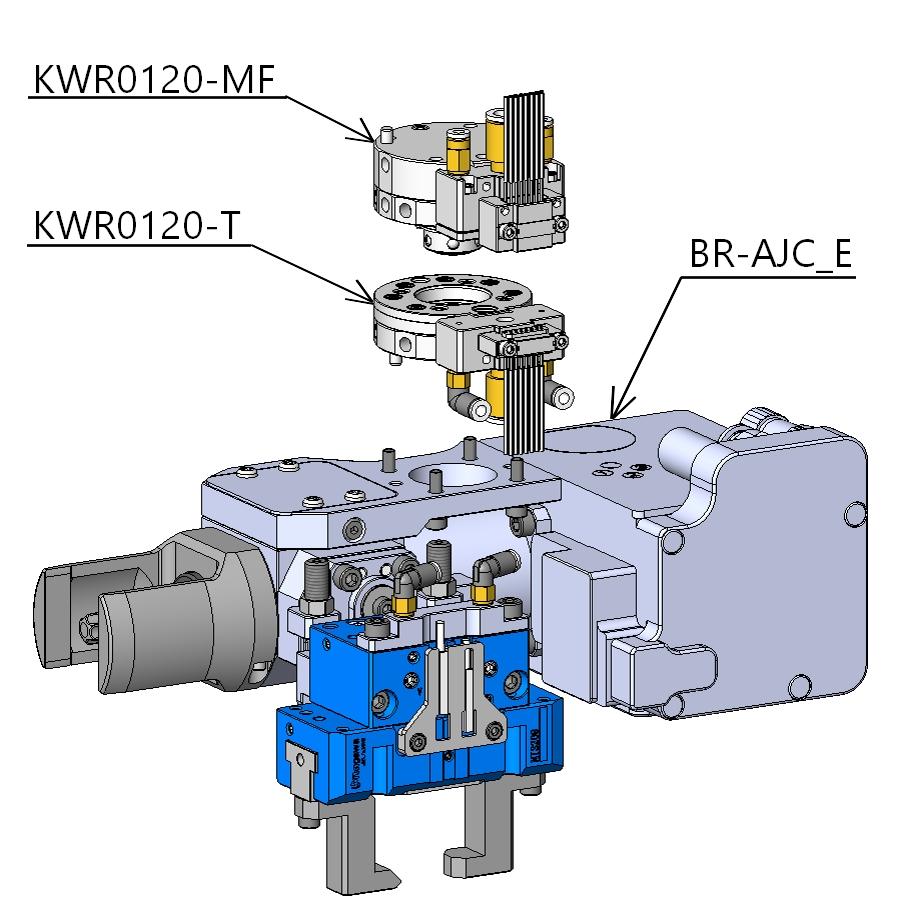

BR-AJC-E and |

|||||||

Main unit (with reaction force lever and torx wrench)

| Model | BR-AJC06E | BR-AJC08E | BR-AJC10E | |

|---|---|---|---|---|

| 2D |  |

|

|

|

| TIF |  |

|

|

|

| DXF |  |

|

|

|

| DWG |  |

|

|

|

| 3D | Parasolid |  |

|

|

| STEP |  |

|

|

|

Dedicated T-nut

| Model | BR-AJC06M | BR-AJC08M | BR-AJC10M | |

|---|---|---|---|---|

| 2D |  |

|

|

|

| TIF |  |

|

|

|

| DXF |  |

|

|

|

| DWG |  |

|

|

|

| 3D | Parasolid |  |

|

|

| STEP |  |

|

|

|

Washer

| Model | BRAJCWS10 | BRAJCWS12 | |

|---|---|---|---|

| 2D |  |

|

|

| TIF |  |

|

|

| DXF |  |

|

|

| DWG |  |

|

|

| 3D | Parasolid |  |

|

| STEP |  |

|

|

Torx bolt with O-ring

| Model | BRAJCBT10 | BRAJCBT12 | |

|---|---|---|---|

| 2D |  |

|

|

| TIF |  |

|

|

| DXF |  |

|

|

| DWG |  |

|

|

| 3D | Parasolid |  |

|

| STEP |  |

|

|

Jaw stocker

| Model | BR-AJC06S | BR-AJC08S | BR-AJC10S | |

|---|---|---|---|---|

| 2D |  |

|

|

|

| TIF |  |

|

|

|

| DXF |  |

|

|

|

| DWG |  |

|

|

|

| 3D | Parasolid |  |

|

|

| STEP |  |

|

|

|

Wide variety of world’s standard power chuck

High gripping force & stability to suit various requirements

Necessary item for Quality control and Safety

Standard Manual Chucks suit to a high-mixture of work pieces and low-volume production.

High performance Rotary Cylinder is integral to for the operation of a power chuck and extracts the maximum capability of the chuck.

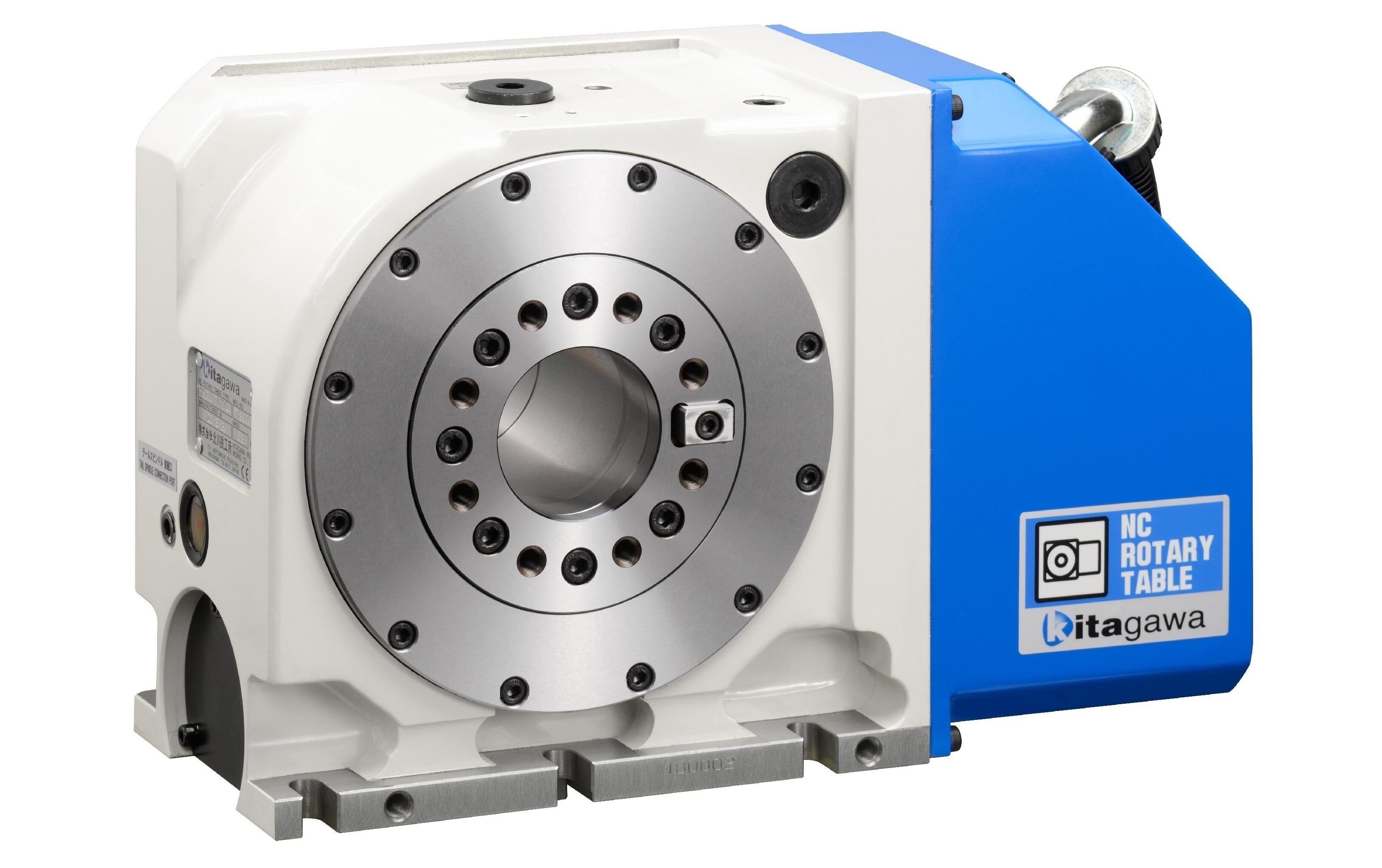

Compact & high accuracy Combination with chuck is available.

Toggle joint mechanism Long jaw stroke

Stationary power chuck with built-in cylinder

Tail stocks, tail spindles, rotary joints, rotary chucks and others

Kitagawa's original grippers with high-quality and high-durability

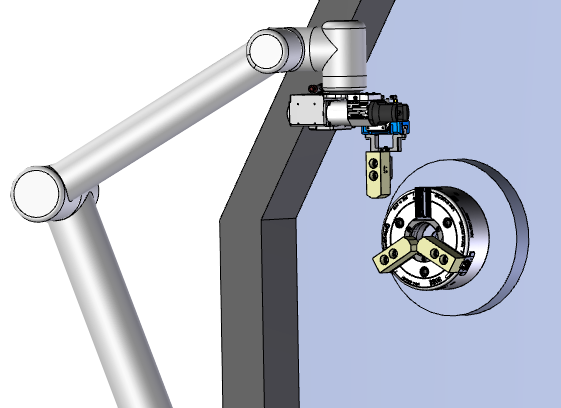

Strongly support factory automation and unmanned operation

Various catalogues can be downloaded.

Various flyers can be downloaded

Information on discontinued products is posted.