Machine Tool

1. High repeatability positioning accuracy of 5μm or less due to the two-surface location.

2. It can be gripped using only the built-in spring, and when the machining load is high, it can be gripped using air clamping.

3. No lubrication and low maintenance.

4. All stainless steel body is rust-resistnt.

5. 4 systems: unclamp, air clamp (boost), air blow or taper hole seating confirmation, end face seating confirmation.

| Engaging force (Spring grip) | 7kN |

| Engaging force (Air pressure 0.6MPa) | 24kN |

| Max. operating pressure | 0.6MPa |

| Repeatability | 5μm |

| Mass | 3.9kg |

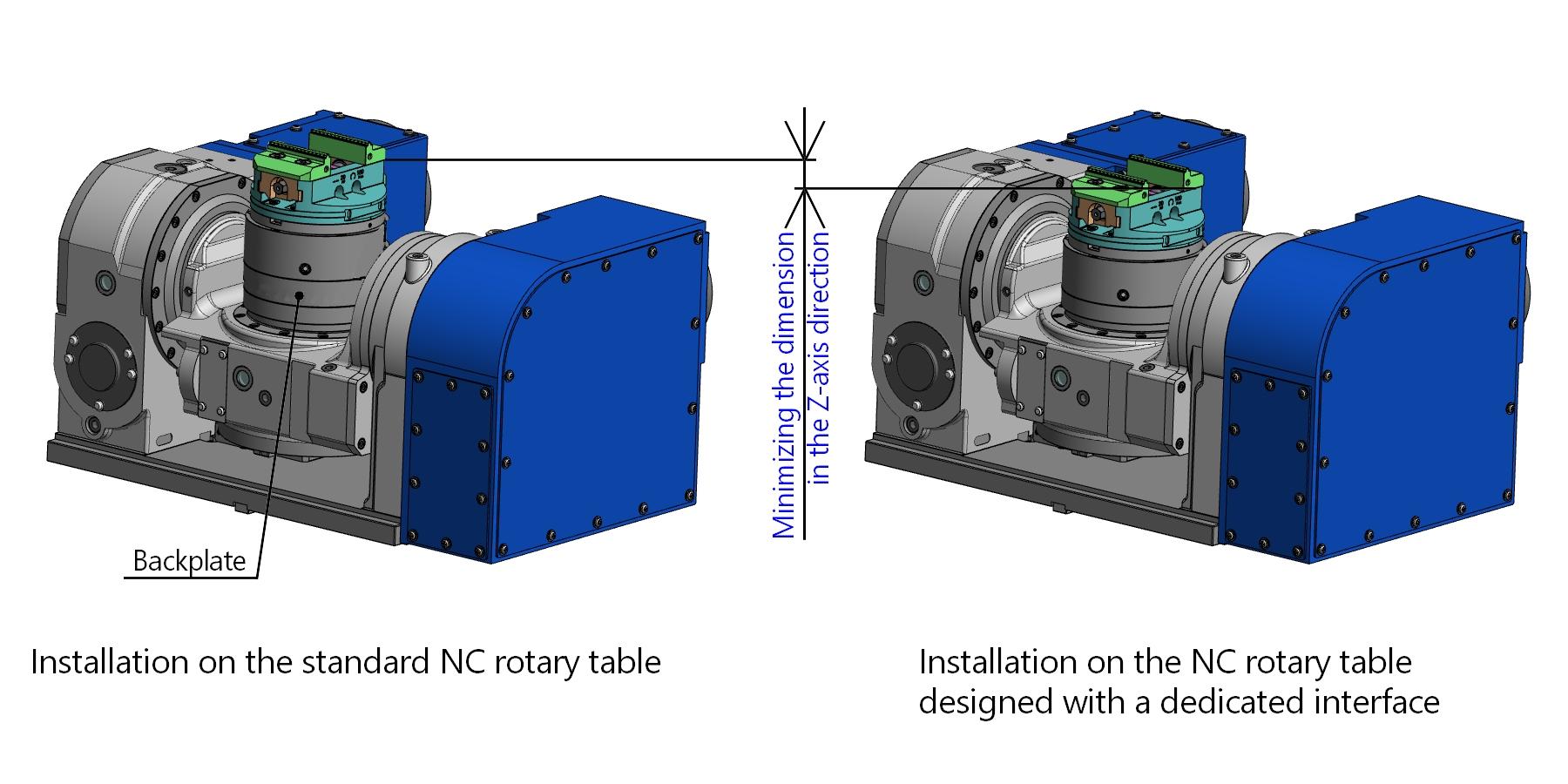

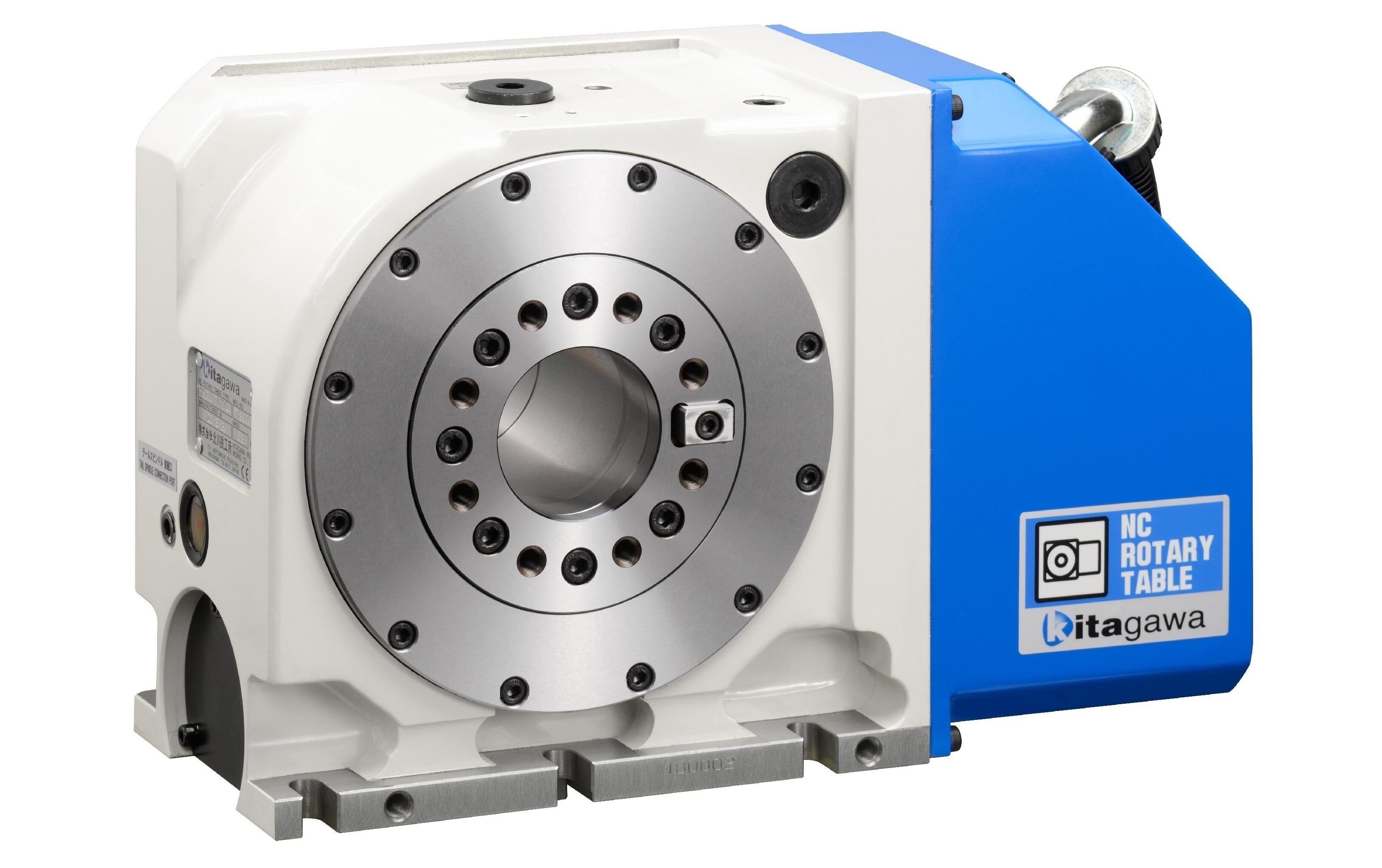

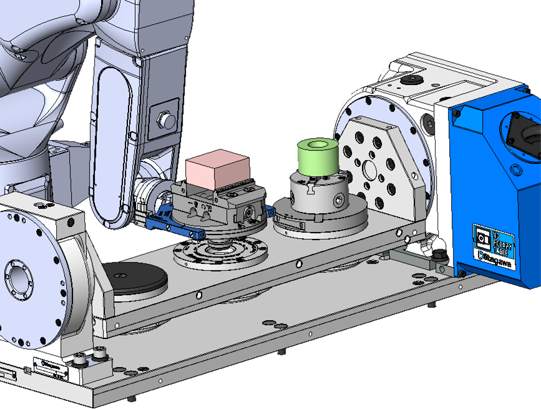

Kitagawa is also the NC rotary table manufacturer. Therefore, the interface on the rotary table side is dedicatedly designed for the pallet clamp mounting. Eliminating the backplate minimizes the Z-axis dimension and expands the machining area.

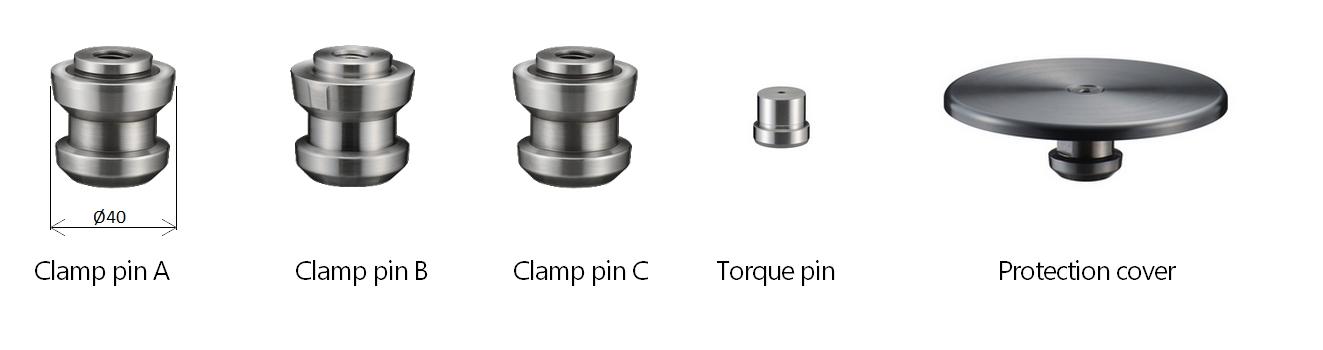

◇Pin

| Part name | Type | Description |

|---|---|---|

| Clamp pin A | PCX40A | Centring pin (Omnidirectional positioning) |

| Clamp pin B | PCX40B | Reference pin (One direction positioning) |

| Clamp pin C | PCX40C | Clamp pin (No positioning function) |

| Torque pin | PCX14T | Phase aligment and torque reception |

| Protection cover | PCX138-PC | Protective cover |

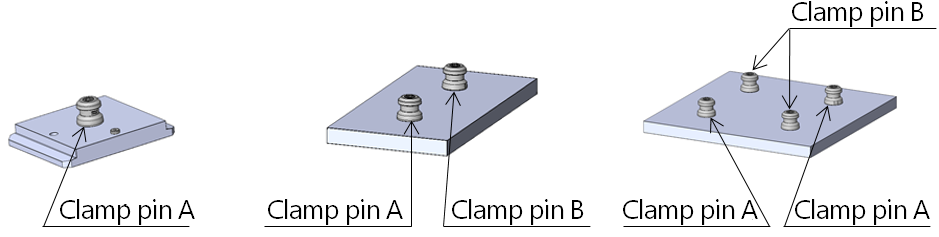

Example of clamp pin usage

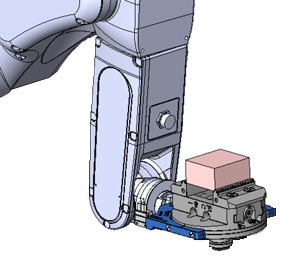

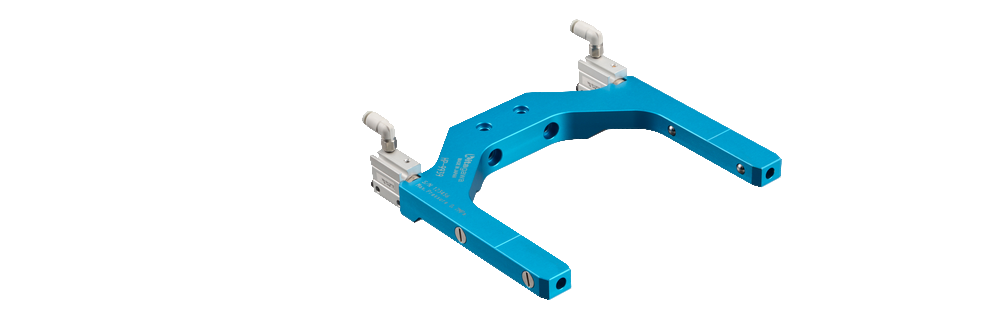

◇Pallet conveying End Effector

Designed specifically for automatic compatible pallets, it is suitable for narrow spaces and short pitch pallet clamps.

(Only in horizontal position during pallet conveying)

Permissible pallet mass: 10kg

Body mass: 0.5kg

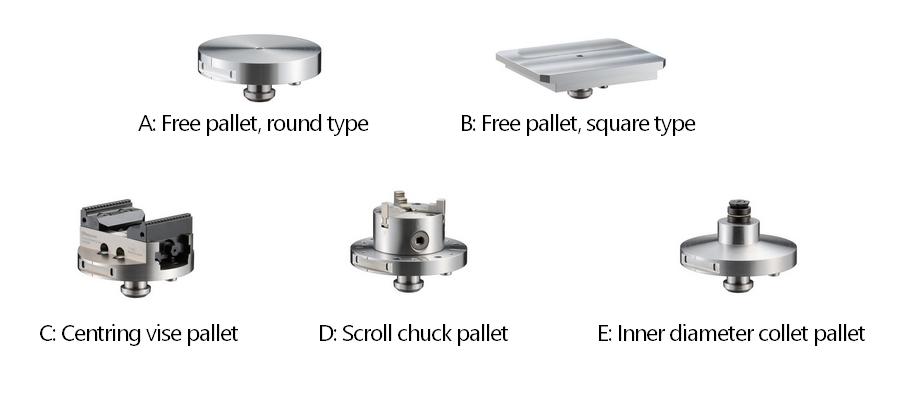

◇Various types of Pallets

| Type | Description | Suitability for automation | Mass (including fixture) | Remarks |

Figure |

|---|---|---|---|---|---|

| PCXP-FRD | Palett (Free round type) | ○ | 2.6kg | For additional machining, Ø139xt20, S45C | A |

| PCXP-FRDAL | Palett (Free round type aluminium) | ○ | 1.3kg | For additional machining, Ø139xt25, A2017 | A |

| PCXP-FSQ | Palett (Free square type) | × | 4.7kg | For additional machining, 199x159xt20, S45C | B |

| PCXP-FSQAL | Palett (Free square type aluminium) | × | 2.2kg | For additional machining, 199x159xt25, A2017 | B |

| V75V13C-P | Centring vise | ○ | 4.3kg | Palette dedicated model | C |

| PCXP-SC3 | Palett (SC-3-106 mounting) | ○ | 4.3kg | 3-inch scroll chuck | D |

| PCXP-SC4 | Palett (SC-4-105 mounting) | ○ | 5.6kg | 4-inch scroll chuck | D |

| PCXP-SC5 | Palett (SC-5-107 mounting) | ○ | 7.0kg | 5-inch scroll chuck | D |

| PCXP-ID08 | Palett (Imao MBID08 mounting) | ○ | 2.8kg | ID gripping, range Ø13.5~20 | E |

| PCXP-ID10 | Palette (Imao MBID10 mounting) | ○ | 2.9kg | ID gripping, range Ø18~27 | E |

| PCXP-ID12 | Palette (Imao MBID12 mounting) | ○ | 3.1kg | ID gripping, range Ø23~35.5 | E |

| PCXP-ID16B | Palette (Imao MBID16B mounting) | ○ | 4.7kg | ID gripping, range Ø29.3~51.5 | E |

| PCXP-ID16D | Palette (Imao MBID16D mounting) | ○ | 6.6kg | ID gripping, range Ø29.3~103 | E |

Note 1) The scroll chuck and Imao inner diameter collet are not included with the pallet. Please arrange them separately.

Note 2) The Imao ID collet chuck MBID is not available from our company.

Note 3) The free pallets may have a thickness tolerance of approximately 0.05mm. If a better tolerance is required, please make additional machining.

Note 4) The specifications of the centring vice are in accordance with the standard V75V13C.

Note 5) The jaws of the centring vise are optional. Please purchase separately.

|

Model |

PCX138 |

|

|---|---|---|

| 2D |  |

|

| TIF |  |

|

| DXF |  |

|

| DWG |  |

|

| 3D | Parasolid |  |

| STEP |  |

|

|

Model |

PCX40A |

PCX40B |

PCX40C |

PCX14T |

|

|---|---|---|---|---|---|

| 2D |  |

|

|

|

|

| TIF |  |

|

|

|

|

| DXF |  |

|

|

|

|

| DWG |  |

|

|

|

|

| 3D | Parasolid |  |

|

|

|

| STEP |  |

|

|

|

|

| Model | HP-9939 |

|

|---|---|---|

| 2D |  |

|

| TIF |  |

|

| DXF |  |

|

| DWG |  |

|

| 3D | Parasolid |  |

| STEP |  |

|

| Model | PCXP-FRD |

PCXP-FDAL |

PCXP-FSQ |

PCXP-FSQAL |

|

|---|---|---|---|---|---|

| 2D |  |

|

|

|

|

| TIF |  |

|

|

|

|

| DXF |  |

|

|

|

|

| DWG |  |

|

|

|

|

| 3D | Parasolid |  |

|

|

|

| STEP |  |

|

|

|

|

| Model | V75V13C-P |

PCXP-SC3 |

PCXP-SC4 |

PCXP-SC5 |

|

|---|---|---|---|---|---|

| 2D |  |

|

|

|

|

| TIF |  |

|

|

|

|

| DXF |  |

|

|

|

|

| DWG |  |

|

|

|

|

| 3D | Parasolid |  |

|

|

|

| STEP |  |

|

|

|

|

| Model | PCXP-ID08 |

PCXP-ID10 |

PCXP-ID12 |

|

|---|---|---|---|---|

| 2D |  |

|

|

|

| TIF |  |

|

|

|

| DXF |  |

|

|

|

| DWG |  |

|

|

|

| 3D | Parasolid |  |

|

|

| STEP |  |

|

|

|

| Model | PCXP-ID16B |

PCXP-ID16D |

|

|---|---|---|---|

| 2D |  |

|

|

| TIF |  |

|

|

| DXF |  |

|

|

| DWG |  |

|

|

| 3D | Parasolid |  |

|

| STEP |  |

|

|

Wide variety of world’s standard power chuck

High gripping force & stability to suit various requirements

Necessary item for Quality control and Safety

Standard Manual Chucks suit to a high-mixture of work pieces and low-volume production.

High performance Rotary Cylinder is integral to for the operation of a power chuck and extracts the maximum capability of the chuck.

Compact & high accuracy Combination with chuck is available.

Toggle joint mechanism Long jaw stroke

Stationary power chuck with built-in cylinder

Tail stocks, tail spindles, rotary joints, rotary chucks and others

Kitagawa's original grippers with high-quality and high-durability

Strongly support factory automation and unmanned operation

Various catalogues can be downloaded.

Various flyers can be downloaded

Information on discontinued products is posted.