Machine Tool

*CE correspondence

Note 1) The gripping accuracy is the Total Indicator Reading of a test bar right after forming jaws to grip a test bar.

Note 2) The repeatability is the Total Indicator Reading of a test bar measured by detaching the formed jaws from the chuck and mounting them again in the same position.

Note 3) Both gripping accuracy and repeatability are the T.I.R. of a test bar at 10 mm above from Kitagawa standard soft jaw.

All the above criteria are based on our internal regulations.

Note 4) Both accuracies for only BR12 are 0.015 mm T.I.R.

Note 5) Download the instruction manual for the optional Tnut-Plus here.

PAT 6345321

PAT 6345375

PAT 6411619

| Model | BR05 | BR06 | BR08 | BR10 | BR12 | ||

|---|---|---|---|---|---|---|---|

| Through-hole (mm) | 33 | 53 | 66 | 81 | 106 | ||

| Gripping Range (mm) | Max. | 135 | 170 | 210 | 254 | 315 | |

| Min. | 7 | 16 | 22 | 31 | 44 | ||

| Jaw Stroke (Diameter) (mm) | 5.4 | 5.5 | 7.4 | 8.8 | 10.6 | ||

| Plunger Stroke (mm) | 10 | 12 | 16 | 19 | 23 | ||

| Max. Draw Bar Pull Force (kN) |

at OD Gripping | 16.6 | 23 | 35 | 49 | 60 | |

| at ID Gripping | 8.3 | 11.5 | 17.5 | 24.5 | 30 | ||

| Max. Static Gripping Force (kN) |

at OD Gripping | 36 | 58.5 | 90 | 123 | 156 | |

| at ID Gripping | 18 | 29.3 | 45 | 61.5 | 78 | ||

| Max. Speed (min-1) | 8000 | 6000 | 5000 | 4500 | 3500 | ||

| Dynamic Gripping Force at Max. Speed (kN) (at OD Gripping) |

15.5 | 22.5 | 36 | 44 | 53 | ||

| Moment of Inertia (kg・m2) | 0.015 | 0.052 | 0.14 | 0.32 | 0.80 | ||

| Net Weight (kg) (with Soft Top Jaws) |

6.2 | 12.8 | 22.2 | 35.8 | 57.0 | ||

| Matching Cylinder | F0933H | SR1453C SS1453K |

SR1566C SS1666K |

SR1781C SS1881K |

SS2110K | ||

| Matching Soft Jaws Note) Jaw-mounting bolts are not included. |

Standard Extra Tall |

Standard Extra Tall Small diameter gripping |

Standard Extra Tall Small diameter gripping |

Standard Extra Tall Small diameter gripping |

Standard Extra Tall Small diameter gripping |

||

| Matching Hard Jaws Note) Jaw-mounting bolts are not included. |

HB04N1 | HB06A1 HB06B1 |

HB08B1 HB08N1 |

HB10AA1 | HB12N1 | ||

| Tnut-Plus (Option) |

TN05PLUS | TN06PLUS | TN08PLUS | TN10PLUS | TN12PLUS | ||

| Outline Drawing | 2D |  |

|

|

|

|

|

| DXF |  |

|

|

|

|

||

| DWG |  |

|

|

|

|

||

| 3D | Parasolid |  |

|

|

|

|

|

| STEP |  |

|

|

|

|

||

| Parasolid |  |

|

|

|

|

||

| STEP |  |

|

|

|

|

||

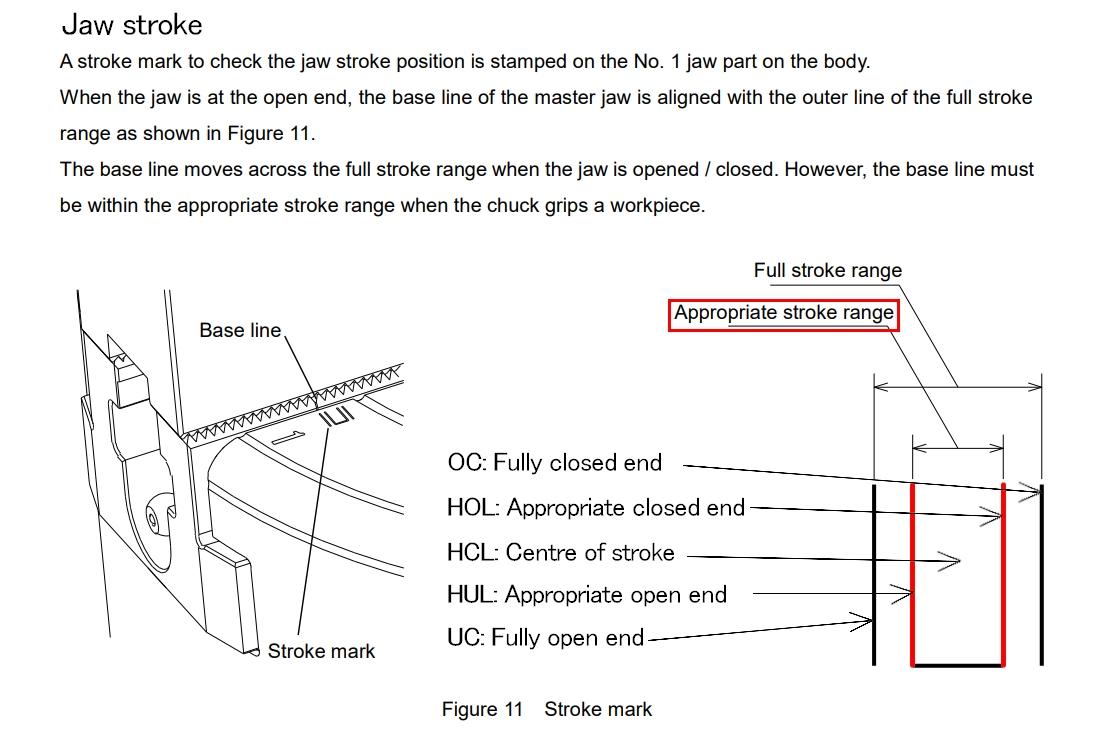

Note) The blue 3D data represents the jaw positions at the fully open (UC) and fully closed (OC) ends for both Parasolid and STEP.

The pink 3D data represents the jaw positions at the centre of stroke (HCL), the appropriate open end (HOL) and the appropriate closed end (HUL) for both Parasolid and STEP.

Jaw stroke

Wide variety of world’s standard power chuck

High gripping force & stability to suit various requirements

Necessary item for Quality control and Safety

Standard Manual Chucks suit to a high-mixture of work pieces and low-volume production.

High performance Rotary Cylinder is integral to for the operation of a power chuck and extracts the maximum capability of the chuck.

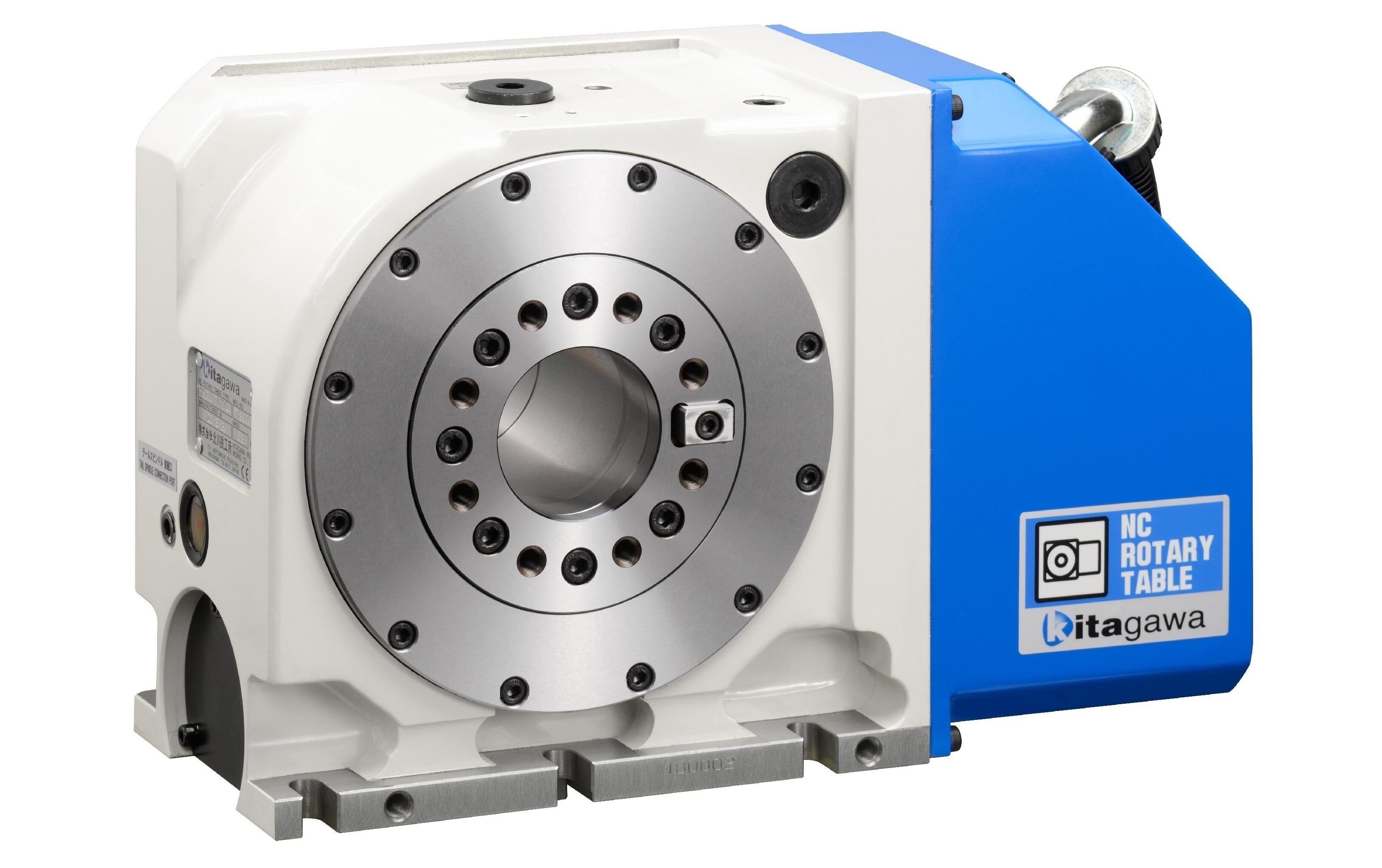

Compact & high accuracy Combination with chuck is available.

Toggle joint mechanism Long jaw stroke

Stationary power chuck with built-in cylinder

Tail stocks, tail spindles, rotary joints, rotary chucks and others

Kitagawa's original grippers with high-quality and high-durability

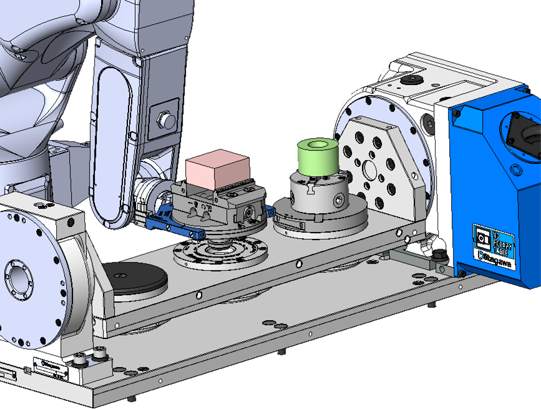

Strongly support factory automation and unmanned operation

Various catalogues can be downloaded.

Various flyers can be downloaded

Information on discontinued products is posted.