Machine Tool

>

| Model | HW-08 | HW-10 | HW-12 | HW-15 | ||

|---|---|---|---|---|---|---|

| Through-hole (mm) | - | - | - | - | ||

| Gripping Range (mm) | Max. | 210 | 270 | 304 | 381 | |

| Min. | 23 | 50 | 50 | 59 | ||

| Jaw Stroke (Diameter) (mm) | 13.2 | 16 | 16 | 17 | ||

| Plunger Stroke (mm) | 17 | 22 | 22 | 25 | ||

| Max. Draw Bar Pull Force (kN) | 16.5 | 23 | 23 | 28 | ||

| Max. Static Gripping Force (kN) | 28 | 42 | 42 | 54 | ||

| Max. Speed (min-1) | 3000 | 2000 | 1500 | 1200 | ||

| Moment of Inertia (kg・m2) | 0.153 | 0.5 | 0.7 | 2.25 | ||

| Net Weight (kg) (with Soft Top Jaws) | 23 | 50 | 58 | 118 | ||

| Matching Cylinder | YW1220R | YW1225R | YW1225R | YW1225R | ||

| Matching Soft Jaws Note) Jaw-mounting bolts are not included. |

Standard Extra Tall |

Standard Extra Tall |

Standard Extra Tall |

Standard | ||

| Outline Drawing | 2D |  |

|

|

|

|

| DXF |  |

|

|

|

||

| DWG |  |

|

|

|

||

| 3D | Parasolid |  |

|

|

|

|

| STEP |  |

|

|

|

||

Note) The 3D data includes two types of the positions of the jaws for both Parasolid and STEP: open end (UC) and closed end (OC).

Wide variety of world’s standard power chuck

High gripping force & stability to suit various requirements

Necessary item for Quality control and Safety

Standard Manual Chucks suit to a high-mixture of work pieces and low-volume production.

High performance Rotary Cylinder is integral to for the operation of a power chuck and extracts the maximum capability of the chuck.

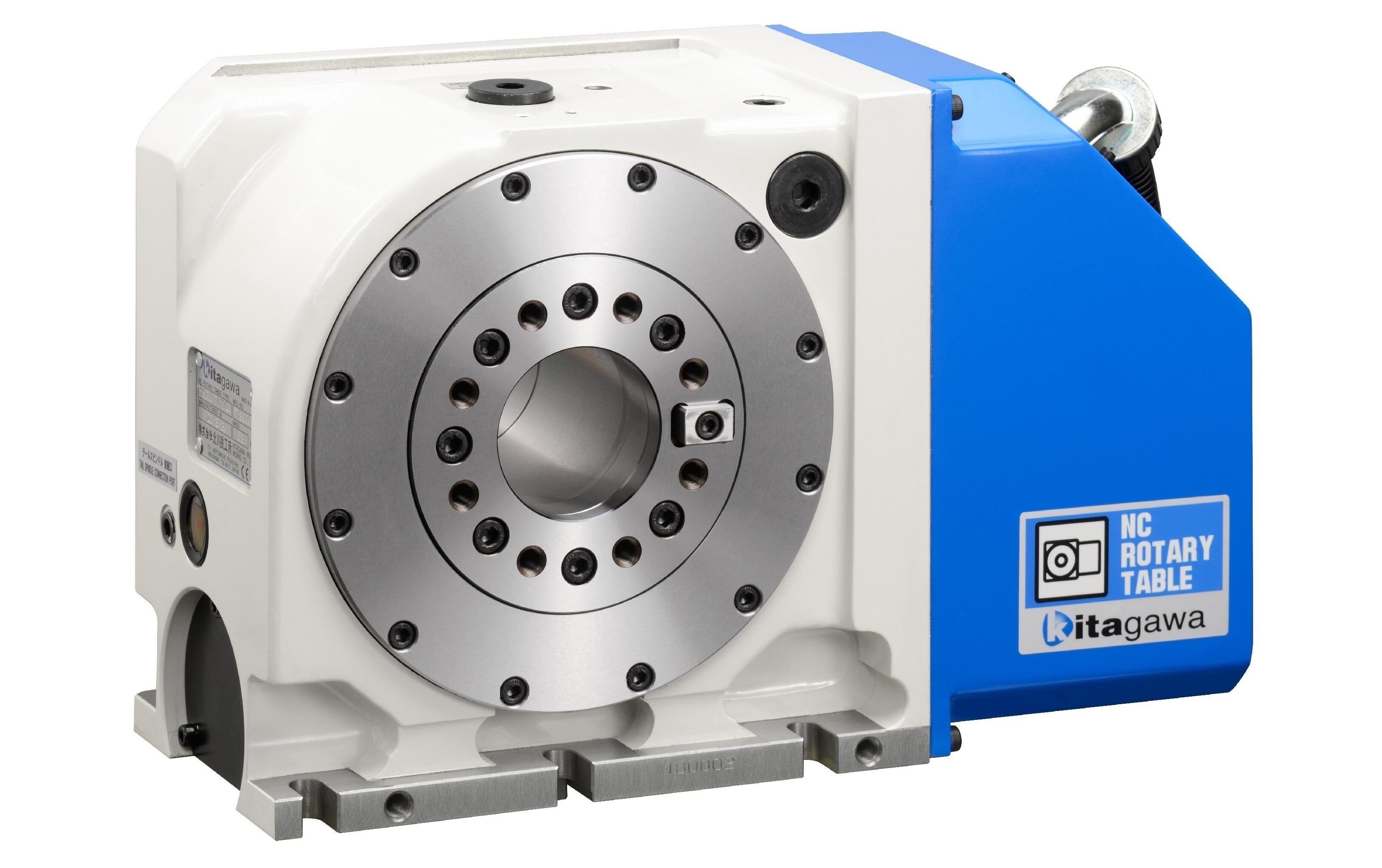

Compact & high accuracy Combination with chuck is available.

Toggle joint mechanism Long jaw stroke

Stationary power chuck with built-in cylinder

Tail stocks, tail spindles, rotary joints, rotary chucks and others

Kitagawa's original grippers with high-quality and high-durability

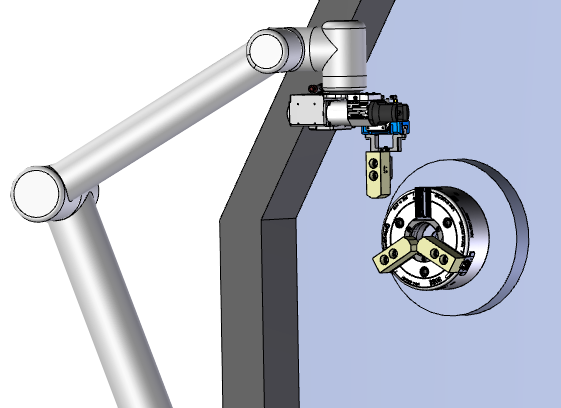

Strongly support factory automation and unmanned operation

Various catalogues can be downloaded.

Various flyers can be downloaded

Information on discontinued products is posted.