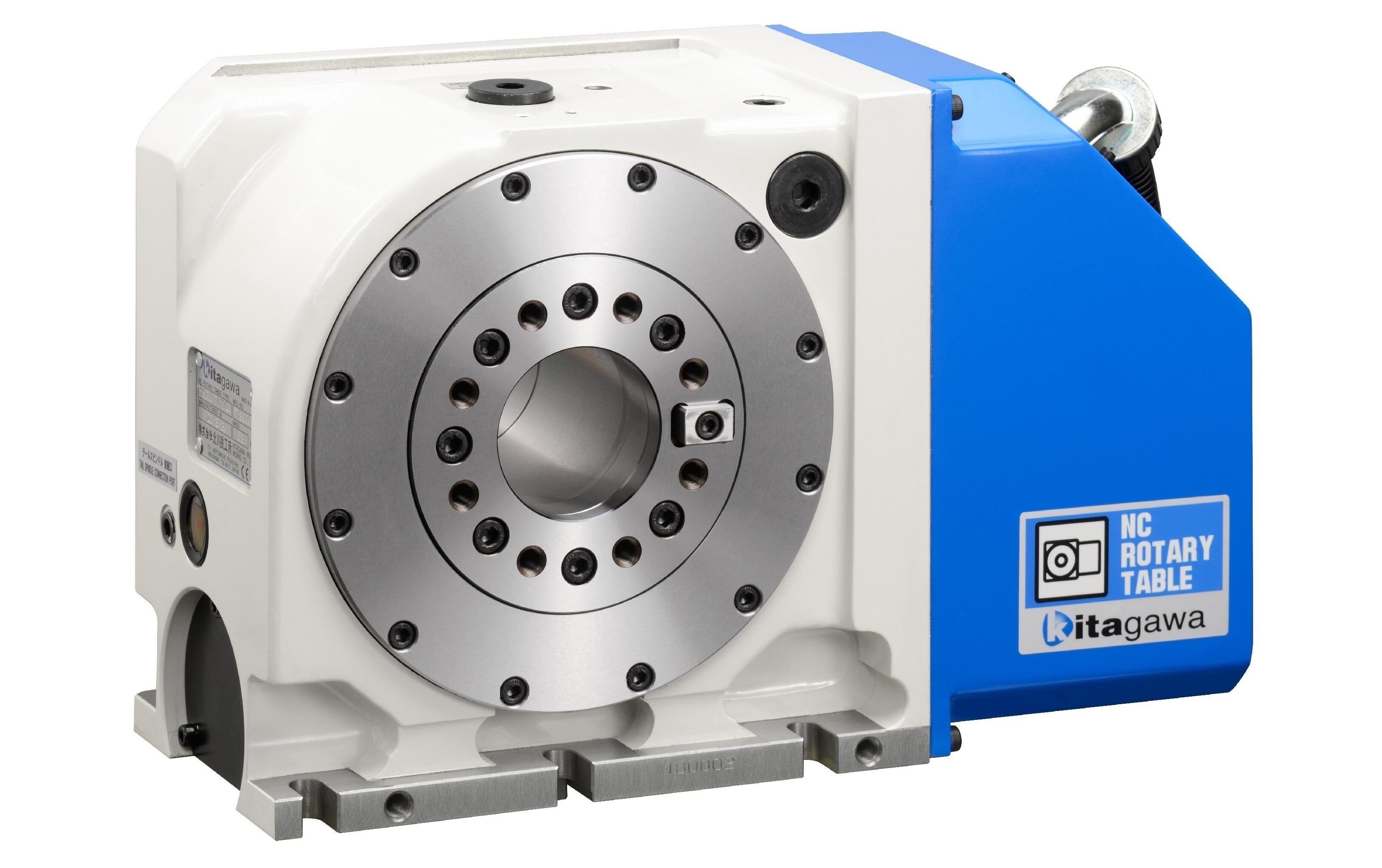

Machine Tool

| Model | MK200R/L | MK250R/L | ||||

|---|---|---|---|---|---|---|

| Right-handed type | ○ | ○ | ||||

| Left-handed type | ○ | ○ | ||||

| Table diameter (mm) | ø 135 | ø 155 | ||||

| Centre hole diameter (mm) | ø 65H7 | ø 70H7 | ||||

| Through hole diameter (mm) | ø 70 | ø 70 | ||||

| Centre Height (mm) | 140 | 180 | ||||

| Clamping method | Pneumatic | Pneumatic | ||||

| Clamping torque (N·m) (at 0.5MPa) |

570 | 1000 | ||||

| Motor axis reduced inertia (kg·m2) |

0.000095 | 0.00041 | ||||

| Servo motor (Fanuc spec.) | αiF4/5000-B | αiF4/5000-B | ||||

| Total reduction ratio | 1/90 | 1/90 | ||||

| Max. rotation speed (min-1) (at motor 3000min- 1) |

33.3 | 33.3 | ||||

| Allowable work inertia (kg·m2) | 1.00 | 1.95 | ||||

| Indexing accuracy (sec) | 20 | 20 | ||||

| Repeatability (sec) | 4 | 4 | ||||

| Mass of product (kg) | 60 | 95 | ||||

| Allowable load | Horizontal (kg) | 200 | 250 | |||

| Vertical (kg) | 100 | 125 | ||||

| Manual tailstock (Option) | MR200RN | MR250RN | ||||

| Tail spindle (Option) | MSRC140/MSR142A | MSR181A | ||||

| Rotary joint (Option) |

7MPa 4-port 25MPa 4-port 7MPa 5-port (Hyd./Pneu. 4 + Pneu. 1) 25MPa 6-port 7MPa 7-port (Hyd./Pneu. 6 + 1Note)) |

7MPa 4-port 25MPa 4-port 7MPa 5-port (Hyd./Pneu. 4 + Pneu. 1) 25MPa 6-port 7MPa 7-port (Hyd./Pneu. 6 + 1Note)) |

||||

| Outline drawing | Kitagawa own controller spec. | 2D |  |

|

||

|

|

|||||

|

|

|||||

|

|

|||||

| 3D | Right hand |  |

|

|||

|

|

|||||

| Left hand |  |

|

||||

|

|

|||||

| 4th axis spec. (FANUC spec.) |

3D | Right hand |  |

|

||

|

|

|||||

| Left hand |  |

|

||||

|

|

|||||

| 7-port rotary joint Outline drawing (Option) |

2D |  |

|

|||

|

|

|||||

|

|

|||||

|

|

|||||

| 3D |  |

|

||||

|

|

|||||

| Option outline drawing |

Tail stock Tail spindle |

|||||

Note) The (+1) port of 7-port rotary joint is a multi-purpose hole for pneumatic port, high-pressure coolant, work seating detection sensor, etc. Please tell our sales staff the purpose in advance.

| Model | MK350 | ||||||

|---|---|---|---|---|---|---|---|

| Right-handed Type | MK350M | MK350R | |||||

| Left-handed Type | MK350H | MK350L | |||||

| Table Diameter (mm) | ø275 | ||||||

| Face plate (Option) | ø350 screw hole spec., ø350 T-groove spec., ø400 T-groove spec. | ||||||

| Centre hole diameter (mm) | ø160H7 | ||||||

| Through hole diameter (mm) | ø160 | ||||||

| Centre height (mm) | 225 | ||||||

| Clmping method | Hydraulic | ||||||

| Clamping torque (N·m) | 6000 (Pressure 3.5 MPa) | ||||||

| Kitagawa controler (Quinte) spec. | |||||||

| Total reduction ratio | 1/90 | 1/120 | |||||

| Motor axix reduced inertia (kg·m2) | 0.0018 | 0.00082 | |||||

| Max. rotation speed (min-1) | 22.2 (at motor 2000min-1) |

16.6 (at motor 2000min-1) |

|||||

| Mass of product (kg) | 200 | 185 | |||||

| 4th axis spec. | |||||||

| Total reduction ratio | 1/90 | 1/120 | |||||

| Motor axix reduced inertia (kg·m2) | 0.0017 | 0.0018 | 0.00081 | 0.0014 | |||

| Servo motor (Fanuc spec.) |

|||||||

| Max. rotation speed (min-1) | 33.3 (at motor 3000min-1) |

25.0 (at motor 3000min-1) |

|||||

| Mass of product (kg) | 185 | 200 | 185 | 220 | |||

| Common specifications | |||||||

| Allowable work inertia (kg·m2) | 7.66 | ||||||

| Indexing accuracy (sec) | 20 | ||||||

| Repeatability (sec) | 4 | ||||||

| Allowable load | Horizontal (kg) | 500 | |||||

| Vertical (kg) | 250 | ||||||

| Manual tailstock (Option) | MR320RN | ||||||

| Tail spindle (Option) | Hydraulic TSR181H45 Pneumatic TSR181A45 |

||||||

| Rotary joint (Option) | 7MPa 6 ports 7MPa 7 ports (Hyd./Pneu. 6+1Note)) 7MPa 8 ports 25MPa 11 ports (Hyd./Pneu. 10+1Note)) 7MPa 13 ports (Hyd./Pneu. 12+1Note)) 7MPa 17 ports (Hyd./Pneu. 16+1Note)) |

||||||

| Outline drawing | Kitagawa own controler spec. | 2D |  |

||||

|

|||||||

|

|||||||

|

|||||||

| 3D | Right hand |  |

|||||

|

|||||||

| Left hand |  |

||||||

|

|||||||

| 4th axis ppec. (FANUC spec.) |

Total reduction ratio | 1/90 | 1/120 | ||||

| Servomotor | αiF 8/4000-B | αiF 12/4000-B | αiF 8/4000-B | αiF 12/4000-B | |||

| 2D |  |

|

|||||

|

|

||||||

|

|

||||||

|

|

||||||

| 3D | Right handed |  |

|

||||

|

|

||||||

| Left handed |  |

|

|||||

|

|

||||||

| 17-port rotary joint Outline drawing (Option) |

2D |  |

|||||

|

|||||||

|

|||||||

|

|||||||

| 3D |  |

||||||

|

|||||||

| Option Outline drawing |

Tailstock Tail spindle |

||||||

Note) The (+1) port of rotary joint is a multi-purpose hole for pneumatic port, high-pressure coolant, work seating detection sensor, etc. Please tell our sales staff the purpose in advance.

To prevent potential issues caused by chips or debris when using the cradle jig, please read the following instructions carefully.

Wide variety of world’s standard power chuck

High gripping force & stability to suit various requirements

Necessary item for Quality control and Safety

Standard Manual Chucks suit to a high-mixture of work pieces and low-volume production.

High performance Rotary Cylinder is integral to for the operation of a power chuck and extracts the maximum capability of the chuck.

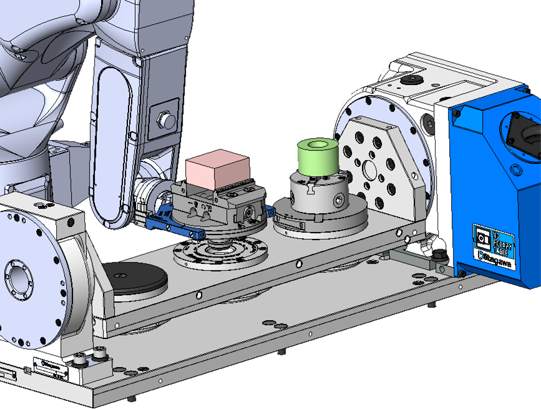

Compact & high accuracy Combination with chuck is available.

Toggle joint mechanism Long jaw stroke

Stationary power chuck with built-in cylinder

Tail stocks, tail spindles, rotary joints, rotary chucks and others

Kitagawa's original grippers with high-quality and high-durability

Strongly support factory automation and unmanned operation

Various catalogues can be downloaded.

Various flyers can be downloaded

Information on discontinued products is posted.