Machine Tool

Details of each electrode are displayed by clicking on the kit model name.

The table may not be displayed in its entirety. Please scroll right if necessary.

| Rated voltage |

Rated current |

Kit model |

One each required for both sides |

Applicable cable (Separately sold) |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| <Option |

(Robot side) |

(Gripper side) |

3kg | 7kg | 12kg | 25kg | 50kg | |||||||

| KWRY 0010 |

KWR 0070 |

KWR 0120 |

KWR 0250 |

KWR 0500 |

||||||||||

| DC24V | 2A/1A | Resin connector | 16 poles | J | SWRZ0J0-M | SWRZ0J0-T | ● | ● | ● | ● | ● | - | ||

| 3A | Solder terminal with cable |

15 poles | Cable 1m | C01 | ● | ● | ● | ● | ● | - | ||||

| Cable 2m | C02 | |||||||||||||

electrode Only when connected: IP54 |

16 poles | Cable 1m | U01 | ● | ● | ● | ● | ● | - | |||||

| Cable 2m | U02 | |||||||||||||

| D-sub connector | 15 poles | D | ● | ● | SWRZ0Z0 | |||||||||

| Circular connector (based on JIS C 5432) |

15 poles | G | SWRZ0G0-M | SWRZ0G0-T | ● | ● | SWRZ0E0 | |||||||

| AC200V DC200V |

5A | Compact electric power transmission option |

4 pols | K | SWLZ0K0-M | SWLZ0K0-T | ● | ● | ● | ● | ● | - | ||

| Power transmission option (based on MIL-DTL-5015) |

8 pole | E | SWRZ0E0-M | SWRZ0E0-T | ● | ● | SWRZ0E0 | - | ||||||

| 13A | High current transmission option (based on MIL-DTL-5015) |

10 pole | H | SWRZ0H0-M | SWRZ0H0-T | ● | ● | SWRZ0H0 | - | |||||

| AC/DC240V for power DC24V for signal |

Servo electrode | 6 poles for power for signal |

F01 | SWRZ0F0-M01 | SWRZ0F0-T01 | ● | ● | SWRZ0F0 | - | |||||

| F02 | SWRZ0F0-M02 | SWRZ0F0-T02 | ||||||||||||

| F05 | SWRZ0F0-M05 | SWRZ0F0-T05 | ||||||||||||

| Noncontact waterproof electrode IP67 Compact model |

Number of signals: 4 | NPN |

W | SWRZ0W0-M | SWRZ0W0-T Cable 1m The same for NPN and PNP |

● | ● | ● | ● | ● | - | - | ||

| PNP |

WX | SWRZ0WX0-M | ||||||||||||

| Noncontact waterproof electrode IP67 | Number of signals: 12 | NPN |

V | SWRZ0V0-M | SWRZ0V0-T Cable 1m The same for NPN and PNP |

● | ● | SWRZ0V0 | - | |||||

| NPN |

V5 | SWRZ0V0-M05 | ||||||||||||

| PNP |

VX | SWRZ0VX0-M | ||||||||||||

| PNP |

VX5 | |

||||||||||||

| Ethernet electrode | - | L | SWRZ0L0-M | SWRZ0L0-T | ● | ● | SWRZ0E0 | - | ||||||

【General Cautions for Selecting External Options】

Mounting surfaces for options and extension examples

KWRY0010 / KWR0070 / KWR0120 : One mounting surface

Example 1: Attach two options to option mounting surface

KWR0250 / KWR0500 : Two mounting surfaces

Example 2: Attach options to option mounting surfaces 1 and 2.

Example 3: Mount two options on option mounting surface

Example 4: Mount one option to option mounting surface 1, two options to option mounting surface 2

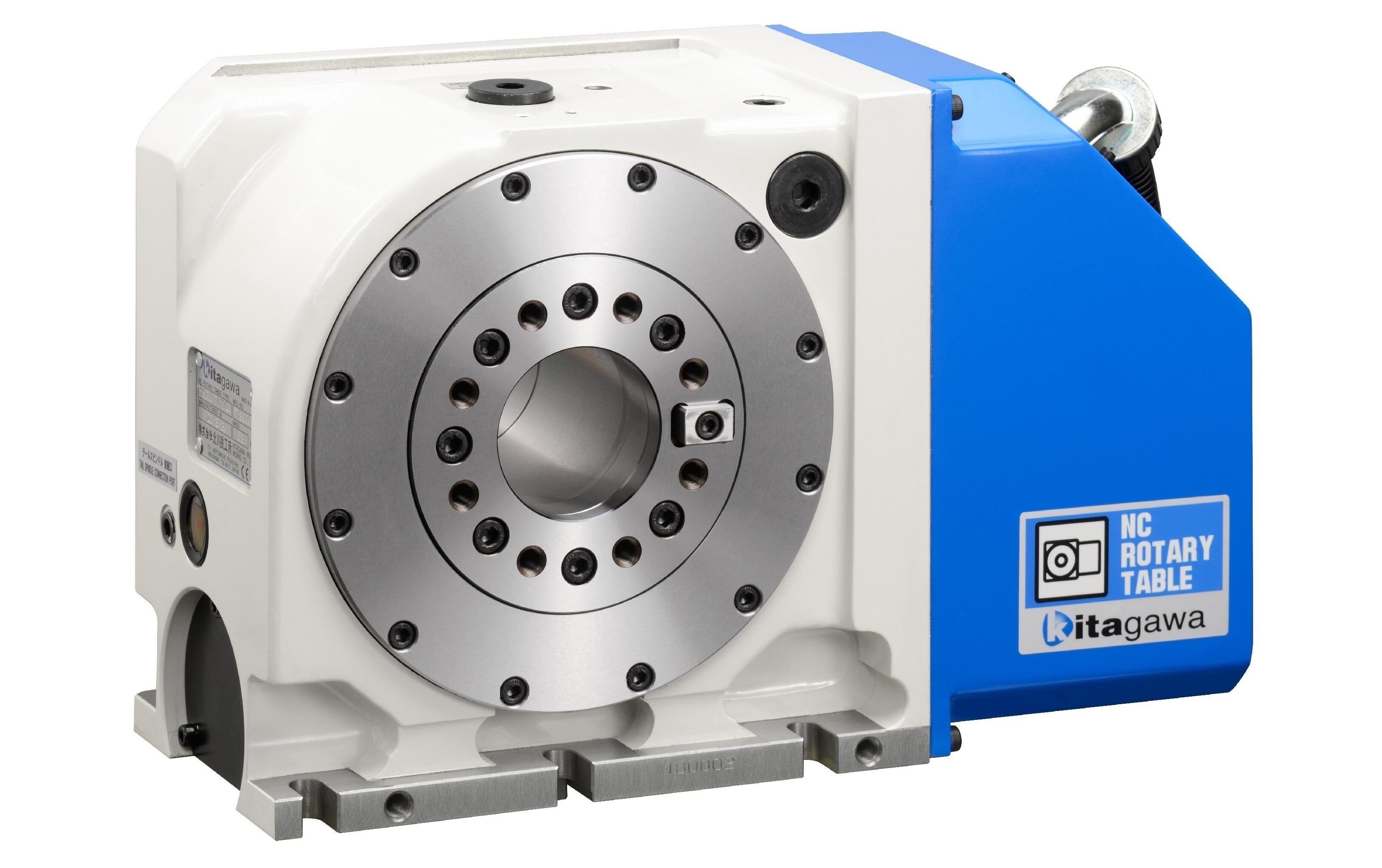

Wide variety of world’s standard power chuck

High gripping force & stability to suit various requirements

Necessary item for Quality control and Safety

Standard Manual Chucks suit to a high-mixture of work pieces and low-volume production.

High performance Rotary Cylinder is integral to for the operation of a power chuck and extracts the maximum capability of the chuck.

Compact & high accuracy Combination with chuck is available.

Tail stocks, tail spindles, rotary joints, rotary chucks and others

Toggle joint mechanism Long jaw stroke

Stationary power chuck with built-in cylinder

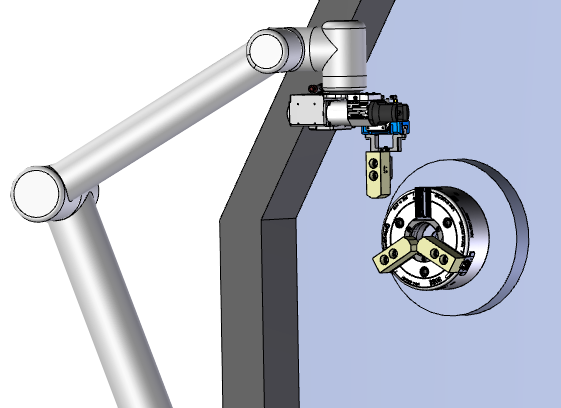

Kitagawa's original grippers with high-quality and high-durability

Strongly support factory automation and unmanned operation

Various catalogues can be downloaded.

Various flyers can be downloaded

Information on discontinued products is posted.